PAGE CONTENTS

Objectives

© Airbus Defence and Space NL

The first phase of the development covered requirements definition, technology investigation, bread-board testing and concept design. A trade-off was made between the concepts designs, and decisions were made on the concept used for the Engineering Model.

Key elements in the design were to increase the pre-load capability, lower the shock induced with the actual release, and ensure a wider operating temperature range. At the same time increase the flexible positioning tolerances and keep a compact and structure that is able to cope with the high mechanical loads.

For the design we have chosen to use a Thermal Knife cutting technology in combination with a VECTRAN cable for the release of the system. The VECTRAN cable offers a high preload capability of 15kN typical load and above 50kN break load.

This model was subjected to a series of tests. The result of the tests were reviewed with ESA

Challenges

Main challenges have been to find the material for the cable and[A1] come up with a design for the cutting mechanism that is compatible with that cable and fits in a design that meets the project requirements. In particular finding the material for the cable and how that can be cut in a controlled manner has been the key objective during the development. After that making a design for the Hold Down that can handle the higher loads.

System Architecture

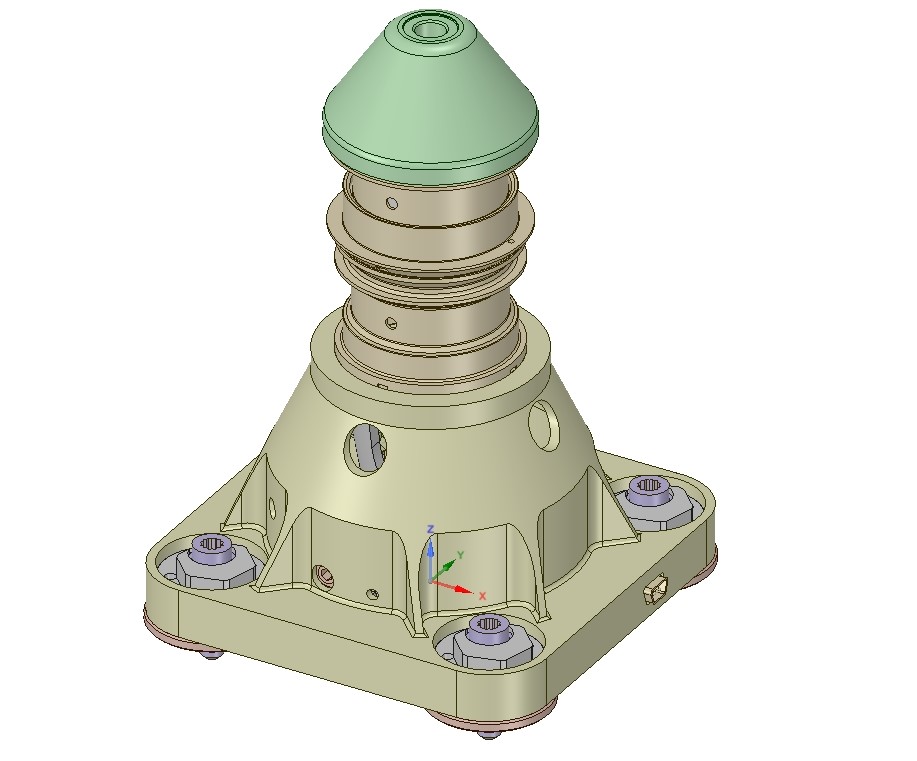

Increased demands from the S/C applications, including satisfying higher margins of safety requires a re-design of the existing ARA mk3 design. The need for higher pre-tension systems from S/C conditions (in certain failure modes) and requiring a larger temperature range than can be met with the ARA mk3 design.

Therefore the NELS development has the approach to extend the pre-tension to 15kN with a design that that has a high level of similarity with the existing ARA mk3 design, and to increase the temperature envelope.

Plan

In summary the project covered the following steps:

- Requirements consolidation

- Complete the conceptual design

- Preliminary design of the EM model and the related tooling and test set-up.

- BB and subsequently EM testing of the Thermal Knives.

- Develop an Alternative for the Thermal Knives

- Restraint cable development testing

- Restraint cable EM testing

- Build the EM NELS, tooling and test set-up

- EM Functional testing

- System characterisation, including pre-load testing, humidity test, random vibration, APTC and repetitive cutting tests

- Test reporting

Current Status

All activities in the ARTES 5.2 project are completed, with the exception of testing a 2nd run of the Thermal Knives and its assembly; ready to progress to formal qualification under a ARTES 3-4 project .

Documents

Companies