PAGE CONTENTS

Objectives

The 3 mains goals of this ESA & EHP co-funded project are:

Achieve a major increase in terms of EHP heat pipes production capacity

Achieve a major decrease in terms of EHP heat pipes production cost

Develop & qualify a new heat pipe product (AG128) for OneWeb project

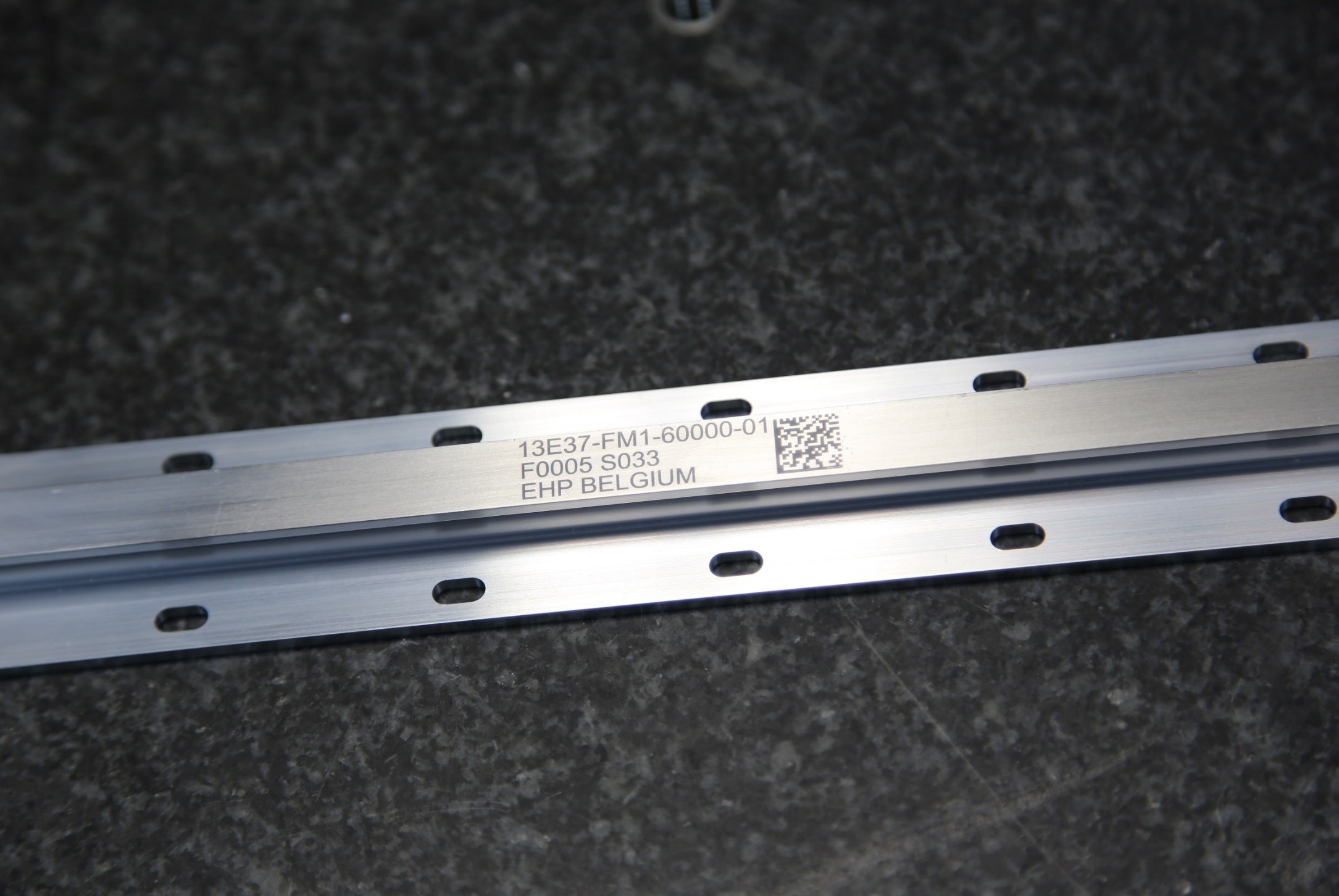

Example of a heat pipe marking with 2D barcode:

Challenges

Although heat pipes are well-known products at EHP since decades, its industrialisation (reliable and stable production of large volumes) remained undeveloped. Improvement of manufacturing processes efficiency and beat rates were challenges.

Example of a heat pipe batch during manufacturing:

System Architecture

Heat pipes are used at spacecraft level for their thermal control. They are mounted on panels or embedded into panels.

Plan

Several phases of industrialization were defined and deployed within EHP workshop in order to implement gradually the updates.

Current Status

Project is successfully completed.

This huge increase of the EHP deliveries transformed EHP into a major worldwide space heat pipes manufacturer.

This also permitted EHP:

- To extend its marketshare in traditional sectors (European SatCom)

- To reach new markets (US satellite manufacturers)

From a socio-economic point of view, deployed production line creates 11 full-time jobs at EHP (+ indirect jobs e.g. subco level)

Beyond the scope of this ESA project:

Over the years, EHP has grown from a small 600m² facility to working areas spread over 3 buildings for a total of 4500m².

This is not enough for the activities forecasted in the next years With the major OneSat project arriving, and with our heat pipe production continuing to grow, EHP needs much more space.

In 2019, the idea of a new modern building was put on the table. Two years later, in May 2021, the work of a brand new 10 000m² facility has begun

New infrastructure consists of 8000m² of industrial areas, including a 2000m² clean room for the assembly of our thermal and deployable systems. Additionally, it includes a nice 2000m² office building that will offer a well-being working environment to all of us.

The first part of the project, the industrial hall and half of the clean room, are to be delivered in the beginning of 2022. The offices and the rest of the clean room are to be available 6 months later, and the final industrial areas for machining and logistics in the beginning of 2023

Related Links

Companies