PAGE CONTENTS

Objectives

The overall objective for the ARTES 3-4 project is to establish TRL 8/9 and develop in parallel the following aspects:

– Generic material qualification for radiator and straps

– Specific development for thermal straps

The objective was to qualify using EQM models after the engineering, manufacturing and testing activities of a representative radiator and a thermal strap design. By the fact that the two products HiPeR Radiator and HiPeR Flexlinks represent extreme cases in the HiPeR product portfolio, the project will enable a relatively low-risk PFM approach for other HiPeR products such as East-/ West radiators and radiators / straps for Science / Earth Observation missions.

Challenges

The generic challenges for the HiPeR program are:

– Qualification of the materials used in the design for the relevant space environments as these materials have not been used previously on a spacecraft application.

– Ensuring that the product is able to meet cleanliness requirements due to the possible particle shedding nature of the functional materials.

– Development of internal processes for handling of these new materials that are used in the HiPeR products.

The specific challenges of the HiPeR Flexlinks are:

– Development of a generic design that is modular so that a large product base is able to be produced from a limited number of building blocks

The specific challenges of the HiPeR radiators are:

– Development of a scalable radiator with performance criteria that can be traded for specific mission scenarios (specific mass performance [W/kg] vs thermal performance [W/m2] )

– A robust, yet simple product design that allows a functional solution despite specific material mechanical weaknesses.

System Architecture

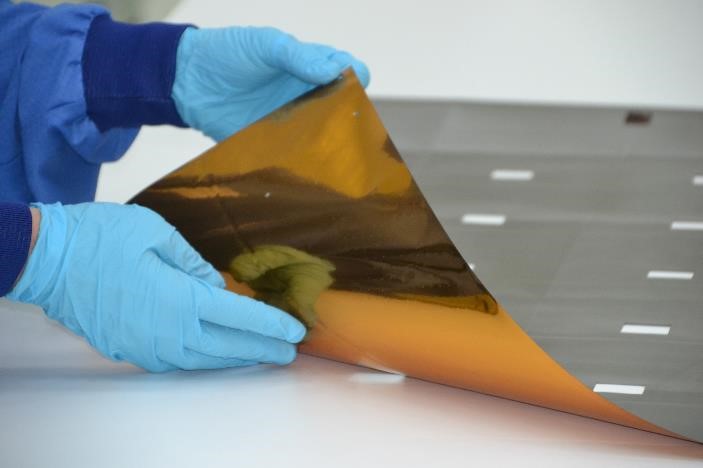

Airbus DS NL’s HiPeR technology is based on Pyrolytic Graphite manufactured by decomposition of polyimide film precursor. This is a specific type of Pyrolytic Graphite, selected for its superior thermal and mechanical properties and low cost.

This material is used in commercial electronics products (smartphones, tablets and computers) and is therefore widely available, and not susceptible to import restrictions (e.g. ITAR-free).

All HiPeR products rely on this material within its system architecture to efficient transfer heat from point to point with thermal interfaces provided for coupling between heat sources and heat sinks.

Plan

N/A

Current Status

The Artes 3-4 project was completed in Q1 of 2021. A catalogue of standard components for the HiPeR Flexlinks available for procurement can be found at the Airbus product Webpage.

The HiPeR Flexlinks currently have a technology readiness level of 9 after full material level qualification (as part of this Artes 3-4 program) and significant launch heritage including:

– Mega constellation: For the delivery of 900 thermal straps in just a few months an in-house industrialised production line was prepared, with a maximum manufacturing output of 26 thermal straps/day. These straps are currently flying.

– SOLO / SoRa: For this mission to the Sun, high performance requirements were applicable. These straps are currently flying.

– Sentinel-5: Thermal straps developed for cooling the Optical instrument, which has very low operating temperatures (-150°C). To be launched soon.

– JUICE: thermal straps for the RF instrument on-board this deep space mission to Jupiter. To be launched soon.

HiPeR Radiators are in continued development with significant progress made recently to establish a robust radiator product using the qualified materials from this program.

Customer testimonials

“We faced the need to combine high thermal conductance with mechanical de-coupling and low mass, using proven technology. HiPeR Flexlinks offered a solution and the design team at Airbus DS NL greatly helped in optimising the design. We used the additional design margin to improve the performance of our primary payload.”

“Your strap is so flexible, our test equipment can’t measure the stiffness.”