European New Space propulsion system supported by ESA's Core Competitiveness programme gains valuable market successes

With support of ESA's Advanced Research in Telecommunications Systems (ARTES) Core Competitiveness programme funding, Dawn Aerospace and Com&Sens have partnered to develop an innovative smart Composite Overwrapped Pressure Vessel (COPV) propellant tank for Dawn’s propulsion system. Using embedded sensors, the tanks gain additional smart features on top of the traditional high pressure propellant storage.

Dawn Aerospace is a supplier of turnkey green propulsion systems for various classes of satellites. Com&Sens implements fibre optical sensing technologies in composites manufacturing processes. This partnership enabled the development of a highly competitive and effective product, capable to make a disruptive impact in an increasingly competitive satellite market.

COPVs store high-pressure fluids needed in propulsion, scientific experiments and life support systems. Their primary advantage over traditional all-metal vessels is their significantly reduced weight, which is about half that of their metal counterparts. This is crucial for missions where weight constraints are a critical factor.

COPVs allow for the storage of low-cost and non-toxic alternatives to the traditionally used hydrazine-based products, enabling systems and missions to carry larger tanks without compromising on the necessary strength and durability. This is particularly important for operations in orbit, where extreme temperatures and radiation pose significant challenges.

Dawn is now developing the designing and manufacturing 30-150-litre tanks, which are lightweight but maintain resistance to the harsh space environment. In parallel, Com&Sens are developing smart sensors in the COPV winding process, enabling an acceleration of development and more actionable insights into the quality of the COPV in testing and production.

The development of the COPVs has enabled Dawn to secure a large propulsion system contract with a new customer, scheduled to launch in 2026, and through this generated a significant pipeline of larger systems.

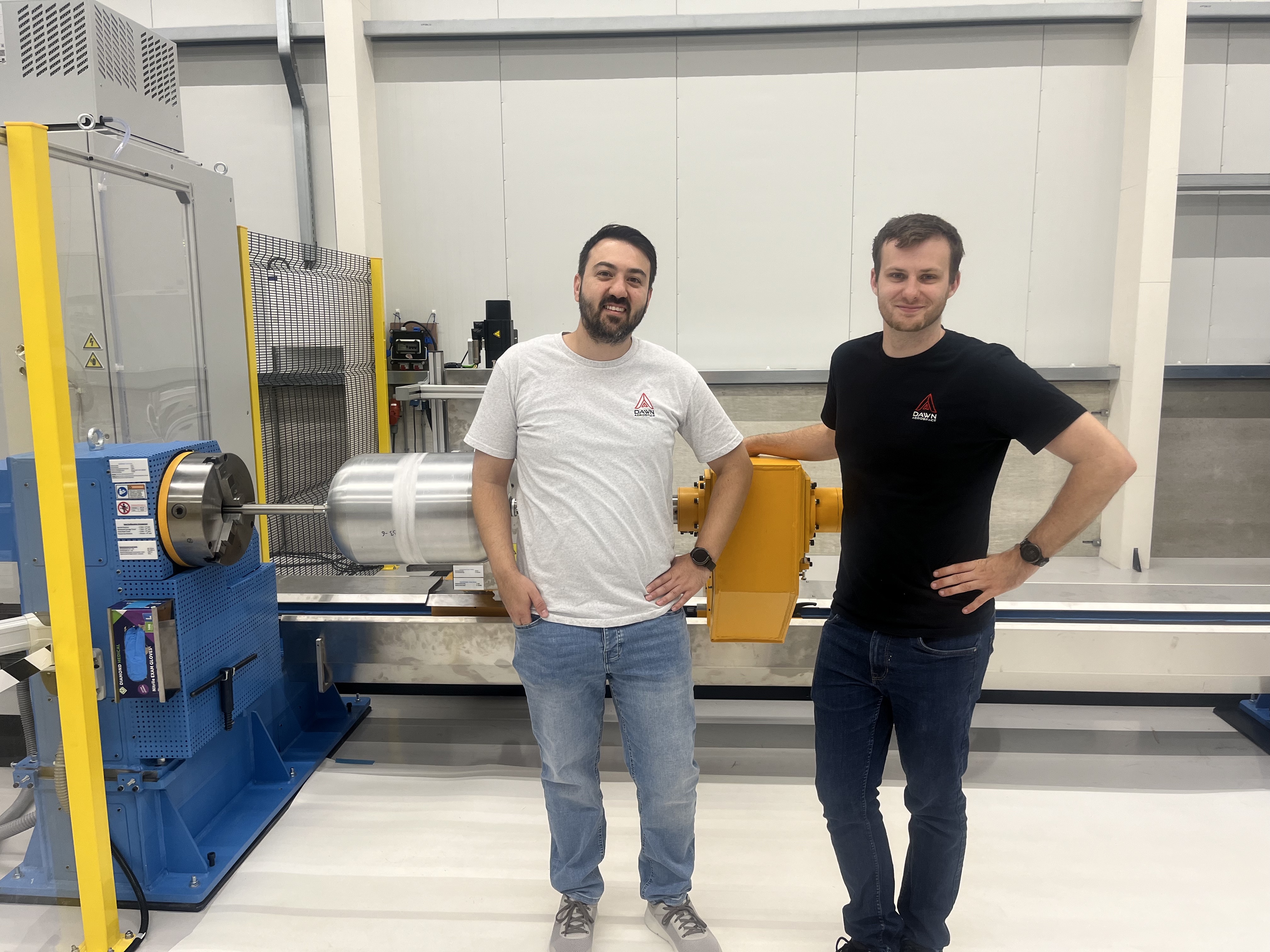

Through the ARTES programme, the relevant technology was de-risked and enabled Dawn to develop and invest in its team and workshop machinery. This June, Dawn enjoyed the delivery and instalment of their new filament winding. The new capabilities will now allow Dawn to offer more scalable products with its larger tank manufacturing abilities, which directly enhances the competitiveness of the European space industry in a global market by servicing larger in-space missions.

“ESA is proud to have supported this great success story with Dawn Aerospace and Com&Sens. This partnership serves as a blueprint for future collaborations across Europe and Canada to drive a sustainable space sector and serve our societies and economies,” said Domenico Mignolo, Acting Head of the Technology and Products Division in ESA’s Connectivity and Secure Communications.

European-made satellites are key to autonomy on Earth, Dawn Aerospace, based in the Netherlands, and Com&Sens, based in Belgium, are supporting this mission to maintain technological leadership, funded through the ARTES Core Competitiveness programme.