Eurostar Neo’s first large scale structure test completed

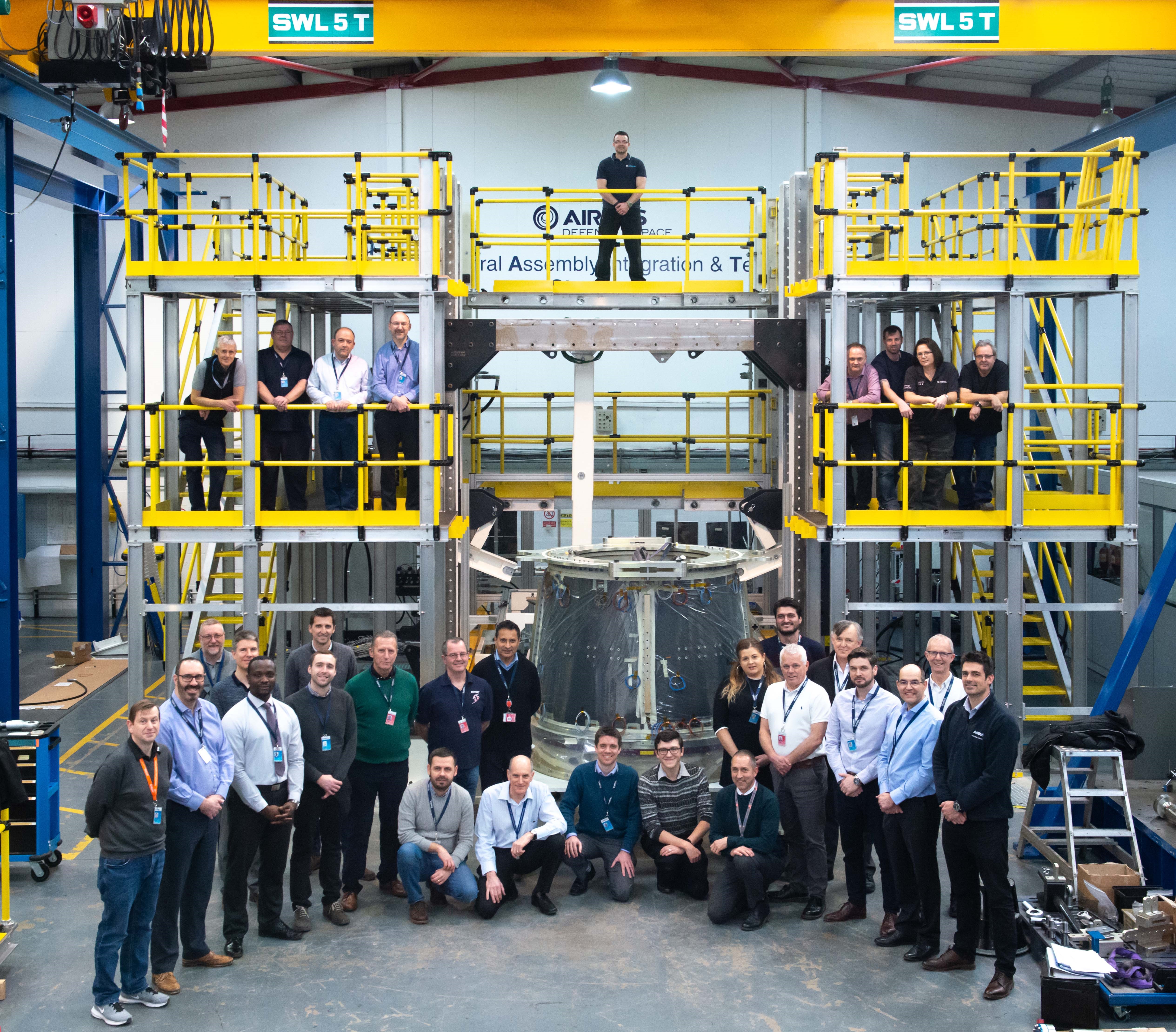

After intense engineering work, Eurostar Neo’s central cone was recently put through rigorous qualification testing, which it successfully completed at the end of April.

The central cone is the backbone of all future spacecraft that will be based on the Eurostar Neo platform, including some that may embark well above 2 tons of telecommunications payload.

To withstand all the loads that such massive satellites will see during their launch, Airbus Defence and Space UK’s mechanical platform team has designed a state of the art competitive conical structure. The carbon fiber part is manufactured in Airbus facilities in Spain and delivered to Airbus Defence and Space UK’s site in Stevenage, where it is completed into a finished product.

It is then tested under high loads in all critical directions.

The next step is to build the first flight structure of the Eurostar Neo platform, which will be used on Eutelsat’s HOTBIRD 13F mission, planned for launch in 2021.

The Neosat programme comprises both Spacebus Neo by Thales Alenia Space and Eurostar Neo by Airbus. It includes development up to in-orbit validation of the new satellite product lines for both companies, allowing European industry to deliver competitive satellites for the commercial satellite market.

Thanks to ESA’s partnership projects such as Neosat, industry is in a position to implement ambitious programmes that can make competitive leaps forward.