PAGE CONTENTS

Objectives

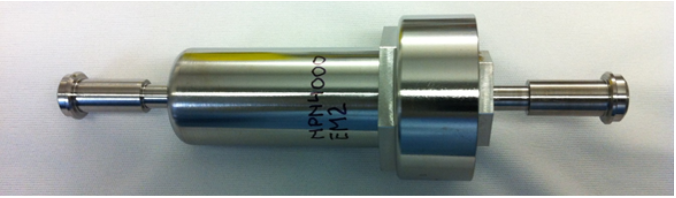

The aim of the project is to assess the applicable requirements and to develop engineering models (EM) of an ITAR free 20µm bi-propellant filter suitable for European geostationary telecoms platforms. The project tasks include the development of a detailed design, manufacturing and verification on three EM and, propellant compatibility testing, and planning for qualification and commercial evolution.

Challenges

The major challenge of the bi-propellant filter is to maintain the performance throughout the required life time of more than 15 years in orbit and be reliable when subjected to the required pressure and temperature environments throughout the operational life time for the most challenging application – a chemical propulsion system for a typical telecommunication satellite in GEO.

System Architecture

The filter design allows installation anywhere on the fluidic line prepared for titanium welding. Filters are typically integrated upstream contamination sensitive components such as regulators, non-return valves, and thruster valves. Liquid filters are used in both mono- and bipropellant systems.

Plan

This project is organised into the following tasks:

- establish a representative requirements specification,

- perform a series of long term material compatibility tests with the materials and coatings of the filter disks intended to be used,

- consolidate the EM design, document and hold a PDR for a 20-micron filter for chemically reactive propellants,

- build and test three EM filters against the agreed requirements specification,

- based on the test results achieved, establish a qualification plan for a follow-on activity

Current Status

Following the project initiation in July 2016, the filter requirements have been established and the development of a detailed design, manufacturing and verification, as well as planning for qualification and commercial evolution, have been performed. Bubble-point test results are consistent between models. The results from the particle filtration tests clearly showed that particles in the 20 µm size range were captured inside the filter. The wetted parts are also shown to be compatible with MMH and MON/NTO propellants. The project has increased the maturity of this product family. The tests show that a baseline filter meet the pressure drop requirement (<700 mbar at a flow rate of 69 g/s), with a pressure drop of ~200 mbar at 68 g/s for a clean filter. However, the requirement is not met after ingestion of 800mg of ISO A4 test dust, which requires a slight redesign of the product. The activity is completed.

Related Links

Companies