-

StatusOngoing

-

Status date2014-11-24

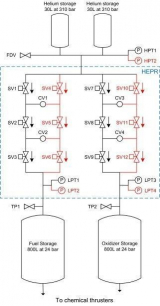

Nearly all current telecommunications platforms use mechanical pressure regulators (MPR) for Helium control in their chemical propulsion system. However, such MPRs have significant drawbacks inherent to their design: fixed set point, high internal leak rate and high minimum operating inlet pressure. An alternative method is electronic regulation. Such bang-bang regulators have been frequently used in Electric Propulsion systems for regulating low-flow, low-pressure Xenon applications. The objective of this work is to demonstrate that using electronic regulators can also be applied to high-flow and high-pressure pressurant gas applications, such as for large (420N) bipropellant thrusters typical of telecommunications platforms. The name given to the resulting product is HEPR: Helium Electronic Pressure Regulator.

N/A

- Adjustable pressure set points along the whole mission

- Minimum required inlet pressure close to the outlet pressure

- Flexibility in exchanging thruster type during AIT

- Removal of pyrovalves thanks to the low internal leak rate

- Three barriers between the pressurant and the propellant tanks

- Possibility to passivate the Helium tank at the end of the mission

The initial study indicates significant improvements in the overall performance of a chemical propulsion system, with mass savings over 20 kg for geostationary satellites with HEPR compared with the ones with MPR.

Several other types of architectures are possible depending on the valve used in the bang-bang regulation and on the expected functionality of the regulator.

Preliminary system level assessments are first conducted on the implementation of a HEPR in a chemical propulsion system and the performance impacts are quantified. A breadboard aimed at demonstrating the HEPR concept is then designed, assembled and tested. The initial estimates, design trade-offs and simulation results are eventually discussed and compared with regards to the outcome of the breadboard campaign.

A breadboard aimed at demonstrating the HEPR concept has been designed, assembled and tested. The initial estimates and design trade-offs have been validated through this breadboard campaign, showing promising results.