PAGE CONTENTS

Objectives

The objective of this activity is to survey existing radome designs and identify relevant performance characteristics applicable to radomes used by mobile satellite ground user terminal antennas operating in Ku-band and Ka-band in different mobile environments.

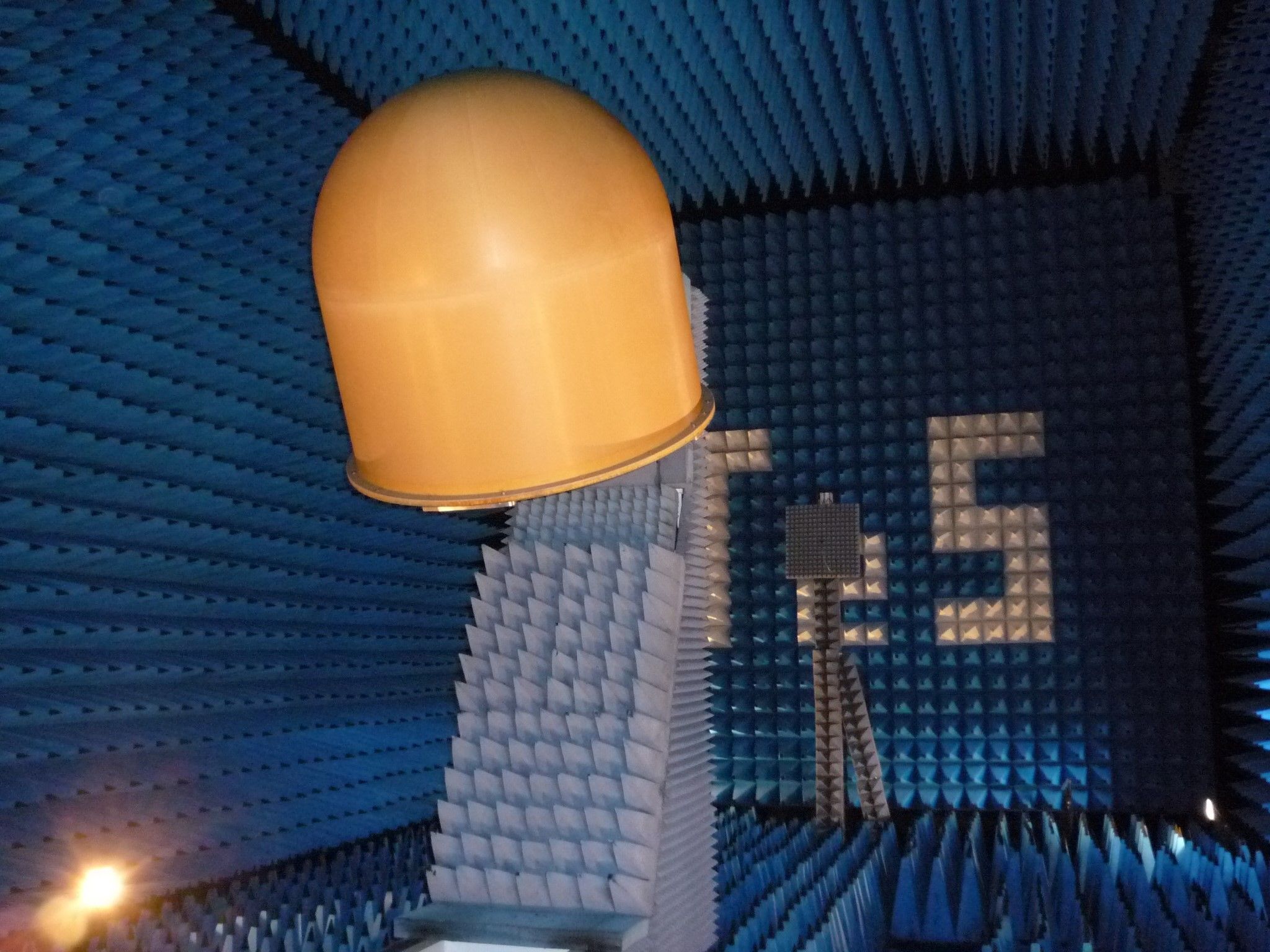

The activity consists in the identification of shortcomings in current radome designs and in the exploration of improved designs to mitigate these shortcomings while trying to minimize the cost. The improved designs has to be verified by defining, building and testing one representative radome Engineering Model suitable for ground terminal to demonstrate the viability of the approach.

TeS Teleinformatica e Sistemi s.r.l., carried out a study on Antenna Radomes for mobile applications (land, maritime and aeronautical) identifying the different performance characteristics applicable to the antenna radomes for mobile user terminal antennas operating in Ku-band and Ka-band. The study activity required to highlight the main short comings in the state of this radome products and to explore possible improvements in the design and development areas. After a deep review of the state of the art of radome for mobile user terminal a set of radome design improvements at sample level have been achieved by TeS for both Ku and in the Ka frequency band. In addition to the state of the art radome materials a quite new material (PP-PP Self Reinforced Polypropylene) has been investigated for radome application as well as the possibility the use of Frequency Selective Surfaces radome solutions. Some of their potentialities are to provide radio-transparency in the Ka band (RX and TX simultaneously) to make use of chip material and to allow significant radome weight reduction while the main shortcomings for such solutions are the technology and the manufacturing processes not completely yet mature for the commercial market.

Challenges

In this study, a picture of the present state-of-the-art situation of radomes for mobile application is identified so as to focalize on criticalities and performance that need to be improved in each specific application (land, maritime and aicraft).

Investigation on possible solutions are explored considering both electromechanical and cost aspect of the radome design, comparing different common and uncommon radome wall configurations and materials.Especially for the newborn Ka and even more the near future Ku/Ka band mobile applications, the challenge is to identify innovative solutions able to provide an RF transparent radome able to withstand the mechanical stress of the specific application with an eye on the cost that always need to be kept reasonable.

Plan

The activity is divided in two technical parts:

PART 1: Trade-Off and preliminary design

Task 1. Survey of the State-of-the-Art, including existing radomes, future trends, definition of requirements.

Task 2. Preliminary design of material buildups, including investigation of material and processes.

Task 3. Manufacturing of Test Samples.

Task 4. Testing of Samples.

Task 5. Preliminary Design of Engineering Model radome for specific application.

PART 2: Design, Manufacturing and Testing of the Engineering Model

Task 6. Detailed design and analysis of the radome.

Task 7. Manufacturing of the Engineering Model.

Task 8. Testing of the Engineering Model.

Task 9. Radome update and Development Plan.

Current Status

Complete. The project is now finished

Companies

TeS

Italy