PAGE CONTENTS

Objectives

CAN bus is an established commercial standard, with countless literature available from the web, numerous electronic components available at low cost, and a high amount of testing equipment available from the shelf to perform rapid prototyping. As such, a CAN bus robust solution for satcom highly benefits from the commercial market efforts to streamline and ease the design of a specific CAN bus solution.

Challenges

Shape the CAN to fulfil satcom requirements:

Challenge is to adapt the CAN bus protocol which has been developed by automotive industry to manage real time tasks to the constrain of the Telecom payloads management.

Integrate CAN to the platform preserving gained heritage:

The proposed solution need to build on the heritage and to cope with existing context. E3000 software and 1553B system bus management have their own capabilities that cannot be over passed.

Offer a high reliability level:

Mission availability is a key feature for telecom payload, the data bus reliability that connects several RF units must cope with that requirement by implementing redundancy and solutions to avoid failure propagation.

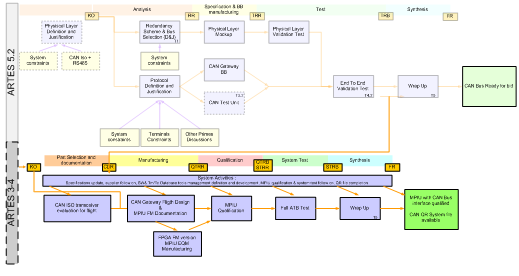

Plan

Main step of the implementation of CAN bus on E3000 is the completion of the design to move from prototype to real flight hardware standard. The qualification of the MPIU with CAN interface EQM is a critical point in order to demonstrate internally and to the end customer that hardware is ready for flight. In parallel the system team need to update the product file with all necessary documentations and tools. All these activities outcomes – MPIU EQM in one side, the complete system file (SW, TM TC database production tools, hardware and software documentation) in the other side are then tested all in one during exhaustive system test on the Avionic Test bench. It is also intended to lead in parallel activities on CAN ISO transceivers components. The following figure shows the overall development logic starting from “CAN bus for platform and payload management” activity followed by “CAN Bus Implementation on E3000” Artes 3-4 development.

Current Status

A full MPIU with CAN interface EQM was built. This unit supported the unit qualification (including mechanical shocks and ESD tests) but also supported a complete end to end system test. Functional tests have been run on the Eurostar E3000 Avionic Test Bench (ATB) that provides test facilities, on board computer and software, system bus and payload interface unit (MPIU). The MPIU, part of the validation environment, embeds the modified board, implementing the CAN/LSSB IP developed in the frame of the study. CAN ISO transceiver has been evaluated: CAN ISO transceiver survey, definition of the part selection criteria, evaluation plan, risk analysis.