PAGE CONTENTS

Objectives

A family of surface tension bi-propellant tanks ranging from 1131L to 1630L was to be produced for a new set of generic Eurostar platforms. For best fit within the platform, the tank domes were to be approximately oblate spheroids, and the tanks were to be skirt-mounted from the upper half of the tank.

A recurring unit cost comparable to the smaller 650L and 750L tanks was the main objective, thus achieving approximately 50% cost saving for the bi-propellant storage of a whole Eurostar chemical propulsion system (i.e. two tanks instead of four will clearly cost half as much, notwithstanding raw material costs and production differences).

Challenges

The main tank development challenges included:

- The tank manufacturing team were parted from the Airbus group shortly after kick-off. They were not able to fully engage with the initially-conceived co-engineering until after “a complete tank design was provided”. The resulting additional design iterations added a significant amount of development time and cost.

- It has proven difficult to maintain geometric repeatability of spin-formed Ti-6Al-4V STA domes at the required scale.

- The baselined tank vibration test facility was at the edge of its capabilities.

System Architecture

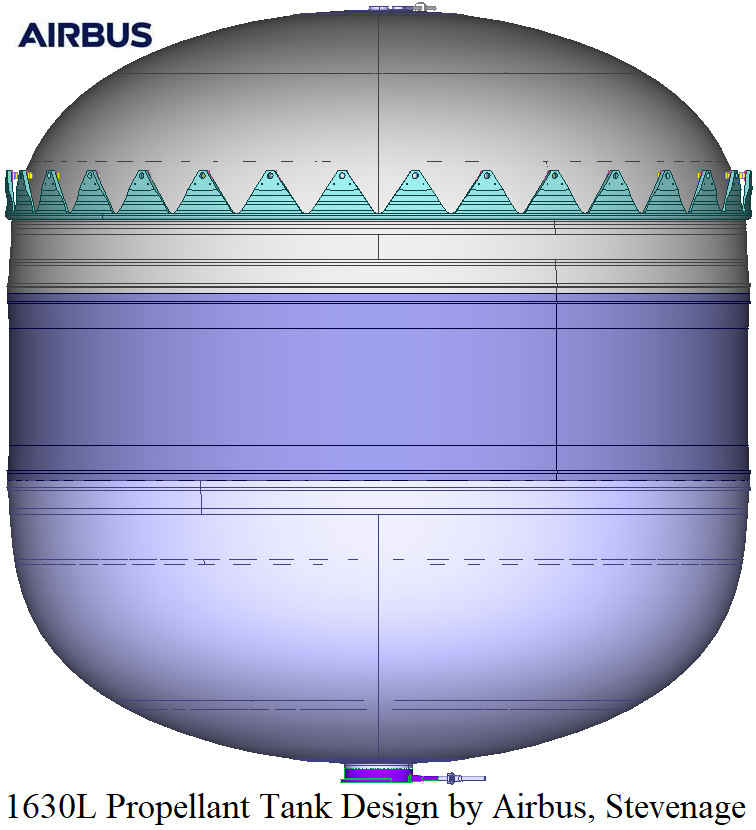

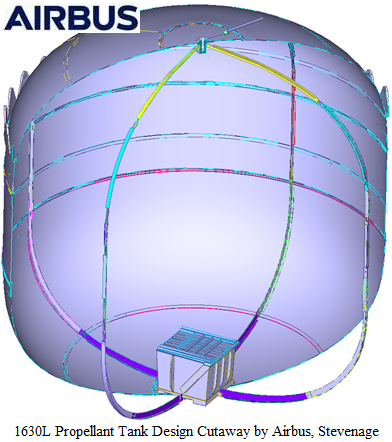

The all-titanium tank comprises an all-welded tank shell with a pressurant port and stub-pipe welded at the top of the tank, and propellant port and stub-pipe welded at the bottom of the tank. The total height of the 1131L and 1630L tanks are approximately 1.08m and 1.43m respectively.

A single-piece mounting skirt is welded to the upper dome, and an MJ10x1.25 self-locking anchor nut is riveted to each of the 32 lugs; the mounting plane is approximately 0.31m below the top of the tank, and, at 1378.4mm across flats, is the widest part of the tank.

A surface tension propellant management reservoir is welded to the inside of the propellant port, and fail-safe propellant acquisition vanes are bolted and wire-locked to brackets welded to the inside of the tank shell.

Plan

Kick-Off

- Define requirements of longer-lead items

- Define preliminary tank interface details.

- Design PMD elements vs. functional requirements and get initial PMD manufacturing feedback.

- PMD material verification.

PMD PDR

- Spin-forming trials.

- Get initial tank design manufacturing feedback & synthesise PMD mechanical environment.

- Detailed PMD design & weld verification.

PMD CDR / Tank PDR

- Tank material verification.

- EQM PMD production & testing.

- Detailed tank design & weld verification.

PMD QTRB / Tank CDR

- QM tank production.

Tank QMRB

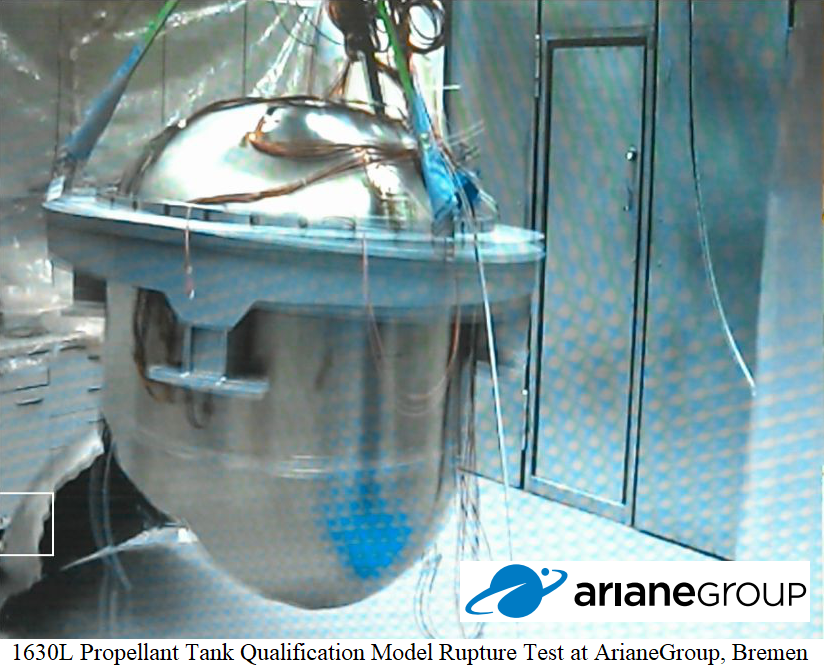

- QM tank testing.

Tank QTRB / PMD&Tank QRB

- Final test reviews.

Current Status

The prime contractor consider the family of tanks to be fully qualified for the Eurostar NEO and JUICE environments, and two 1630L flight tanks are installed on the JUICE spacecraft.

Spin-formed domes in STA condition have proven to have an unacceptably high scrappage rate, so any further orders for this tank will require a significant change in industrialisation strategy, and – most likely – some corresponding changes to the design. Such changes are unlikely to require a new tank qualification, but this is subject to exactly what changes will be implemented, which will depend on trends in customer requirements.