PAGE CONTENTS

Objectives

The objective of this project is to design and develop a modular universal high voltage switching matrix with solid-state components as a modular component for use with Power Processing Units (PPUs).

Targeted Improvements: Especially for telecom platforms with full-electric-propulsion systems the following improvements are targeted with respect to the PPU:

- Reduction of mass/volume/cost

- Improvement of reliability

- Reduction of production time and cost

- Flexibility by modular approach

- Reduction of PPU related components subject to ITAR

Challenges

The project focuses on a switching matrix concept connecting several PPU’s to several thrusters and implementing on-ground or in-orbit configurability in order to:

- adapt to the different operating modes during a typical telecom mission of full-electric spacecrafts

- guarantee electric propulsion system performances even after one or several failures.

The switching matrix should sustain high voltage up to 2000V in order to be usable with all kind of thrusters. Solid state components should be used to design high voltage switches.

System Architecture

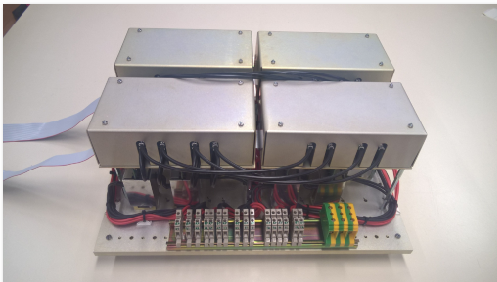

The architecture is focused , for the breadboard, on a 2X2 switching matrix allowing to connect 2 PPU’s with 2 thrusters but this architecture is compatible to NxM switching matrix.

Considering limitations of solid state components, a high voltage line is switched by solid state components whereas low voltage lines are switched by electromechanical relays.

This 2×2 switching matrix without PPU in series feature is composed of:

- Switching matrix nodes including power lines (positive and return lines) as required in the specifications. They are divided in 2 different functions depending on voltage that must be managed:

- 1 high voltage (HV) switching node function whose voltage rating is 2000V. This function is made of solid state components.

- Medium high voltage (LV) switching node function whose voltage rating is 400V. This function is made of electromechanical relays.

- Status functions used to verify the presence of a voltage at each output of a PPU.

- Auxiliary Power Supply (APS) function used to supply switching node and control functions.

- Control functions used to manage TM/TC and control all switches of the matrix.

- Filter Units (FU).

Plan

This project has been divided in 5 tasks:

- Definition of Requirements

- Topology and Technology Trade-Off

The purpose is to highlight optimizations that decrease the number of switches required in a matrix.

The solid state component trade-off includes a market review of available components but also components that will be available in the near future.

- Architecture Design

- Detailed Design

- Detailed design of the blocs constituting the switching matrix

- Establishment of a list of the failures mode of the PPU and the thrusters

- Manufacturing, Verification and Test

Current Status

The project is now achieved at EBB level.

The goals of the contract have been reached.

This project highlighted some specific points that shall be taken into account for future development such as reliability of the high voltage lines and the matrix modularity ( its efficiency can be optimized for a specific thruster ).

This project has lead TAS-B to acquire knowledge about various subjects especially on galvanic isolation during repressuring at 2kV.