PAGE CONTENTS

Objectives

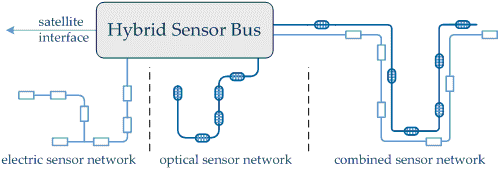

The Hybrid Sensor Bus is a modular sensor measurement system for the interrogation of sensors in bus networks on-board satellites. The system is designed for the geostationary reference platform Small-GEO provided by OHB System AG.

The objective of the HSB development is to provide a new system which allows the acquisition of bus-based sensor networks on-board spacecraft. Transducers are used to convert measurands (e.g. temperatures) locally at the respective measurement points. Information of the measurands are transferred via sensor bus networks to the HSB interrogation unit.

Sensors in classical point-to-point (p2p) wiring can be replaced by sensor bus networks with local transducers. Compared to classical sensing topologies the transducer network solution provides benefits like substantial savings in mass and AIT effort.

Challenges

The fiber-optical interrogation system includes photonic elements which are not available in ESCC compliant versions. Numerous component tests (thermal and radiation) were carried out and the results were considered for the system design.

FBGs suffer from high induced wavelength shifts under radiation due to TID effects. Test series applying a dedicated FBG writing technique were carried out.

FBGs are sensitive both to strain and temperature. A decoupling method in terms of an FBG transducer was introduced.

The processor module shall operate for 15 years allowing later changes in software. For this the processor module is equipped with a special bootloader allowing firmware updates.

System Architecture

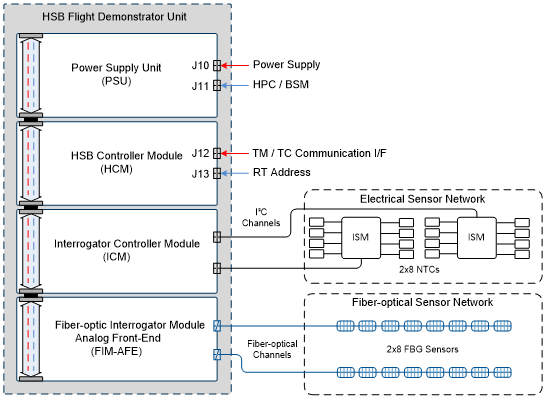

HSB consists of four core modules:

- The Power Supply Unit (PSU) for the generation of secondary power,

- the HSB Controller Module (HCM) with the processor running the application software for interrogation and TMTC,

- the Interrogator Controller Module (ICM) used for the communication with the electrical sensors and to control

- the Fiber-optical interrogator module’s Analog Front End (FIM-AFE) used to interrogate the fiber-optical sensor network.

The modular approach allows to configure the HSB System according to the spacecraft needs like the required number of sensors. HSB can be expanded by additional ICMs and/or FIM-AFEs to query more sensors. This is possible due to stackable frames.

HSB properties:

- Radiation hard up to 100 krad TID for 15 years in geostationary orbit.

- Control of up to 4 interrogator modules.

- Measuring of up to 100 I²C sensors on 4 buses per interrogator module.

- Interrogation of up to 48 FBG sensors on 4 fibers per interrogator module.

- Measurement rate 1 Hz in standard mode and up to 100 Hz in fast mode for single sensors.

- ±0.5 °C temperature sensor accuracy.

- ±100 °C temperature sensor measurement range.

- -20 °C to +65 °C operational temperature range.

- 50 V nominal supply voltage (+42 V to +52 V).

- Power consumption of ≤ 16 W (configuration with one interrogator module).

- Mass of ≤ 3.5 kg (with one ICM and FIM-AFE module).

- 15 y operational life time.

- Unit size of 218 x 166 x 115 mm³ (L x W x H).

- Selectable MIL-Bus/CAN/SpaceWire interface.

- 5 MB RAM for > 2 h full sampling storage.

- MIL-STD-1553 communication interface (CAN for future foreseen).

Plan

Phase 1 of the project included a detailed design definition phase and ended with breadboard models of all subsystems. Phase 2 ends with a complete Engineering Model (EM) of all modules considering the interface requirements for SGEO platforms. To prove the concept an environmental test consisting of a thermal-cycling test and an EMC test was carried out.

Current Status

The design carried out in Phase 1 resulted in a breadboard assembly which was successfully tested. Component tests and selection for the photonic elements was carried out with success.

The EM development in Phase 2 could be finalized and environmentally tested for performance verification.

The project has been completed.