PAGE CONTENTS

Objectives

The objective of this activity is the development of a low profile dual polarization professional mobile user terminal suitable for trains and long-range buses applications.

The target antenna uses only one radiating aperture for all the three bands and offers improved performance compared to the available low profile antenna solutions in the target market. The design, supported by a suitable manufacturing technology, allows the reduction of the overall antenna weight, swept volume as well as to decrease the overall manufacturing recurrent cost.

The antenna is suitable for a completely mechanical scanning pointing system (MSA). A full-scale representative breadboard has been manufactured and tested covering three bands: Ku-band, Ka Band for commercial applications (19.2-20.2 GHz; 29.0-30.0 GHz), Ka-Band for institutional ones (20.2-21.2 GHz; 30.0-31.0 GHz)

Challenges

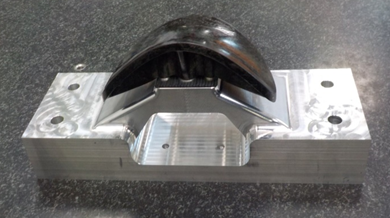

In the low profile railway antenna development the compression molding technology, based on the use of carbon SMC, has been selected as the best compromise for cost and weight reduction w.r.t. traditional manufacturing technologies (milling machining and autoclave curing). When compared to metals and other composite fabrication methods, carbon SMC provides the following advantages:

-

Very Complex Geometries

-

Possibility to easily replace metal components by nearly matching the metal part geometry

-

Possibility to add inserts and rib stiffeners

-

Dimensional control and stability

-

Finished part low cost with the ability to make high volumes

-

Short manufacturing lead time w.r.t carbon fibre legacy technology

System Architecture

The LUPA mechanical scanning antenna is composed by the following main components:

-

Three reflector optics including sub-support

-

Ku feed

-

Ku rotatable polarizer

-

Ku OMT)

-

Ka feed

-

Ka rotatable polarizer

-

Ka OMT)

-

Mechanical Ku/Ka band mirror switch

Plan

The project plan foresees the following reviews:

-

K0 (Kick-Off Meeting) Project plan presentation and first review of the requirements at system level

-

PDR (Review the state-of-the art solutions, Identification of manufacturing and assembly techniques, Identification of a single preferred baseline configuration

-

DDR (RF design, mechanical-thermal design, fabrication defined, sensitivity analysis, fully representative bread-bard proposal, test plan)

-

CDR (RF design, mechanical-thermal design, fabrication defined, sensitivity analysis, fully representative bread-bard design, risk analysis, test plan)

-

TRR (Manufactured parts of Breadboard, assembly, Test procedures)

-

TRB (Breadboard model experimentally verified, Analysis and experimental results correspondence)

-

FR (Final Review) with the aim of analysing the results of the performed test on the Demonstrator models and to verify the compliance with the defined requirements, lesson learnt, product development plan)

Current Status

Project Final Review, held by 1st March 2022, completed the project activities; CCN/next phase possible steps are under evaluation. The feasibility of the antenna terminal performance and the SMC manufacturing technology have been demonstrated along the study project by using a full-scale antenna prototype. Functional electrical test have been performed at Airbus Italia (Rome) premises by using a spherical near field RF measurement system. The effort required to complete the antenna terminal development with the maturity level of a product ready to the operational environment and able to approach the market has been evaluated and reported in the product development plan.