PAGE CONTENTS

Objectives

The Project had the aim to investigate how the application of metamaterial concept, and more specifically the metasurfaces, thanks to their inherent greater technological simplicity with respect to the 3D counterpart of artificial materials, can improve the performance, reduce the mass and dimension, and simplify the manufacturing of horn antennas, in their different applications in space field (single feeds, cluster feeds, global horns etc).

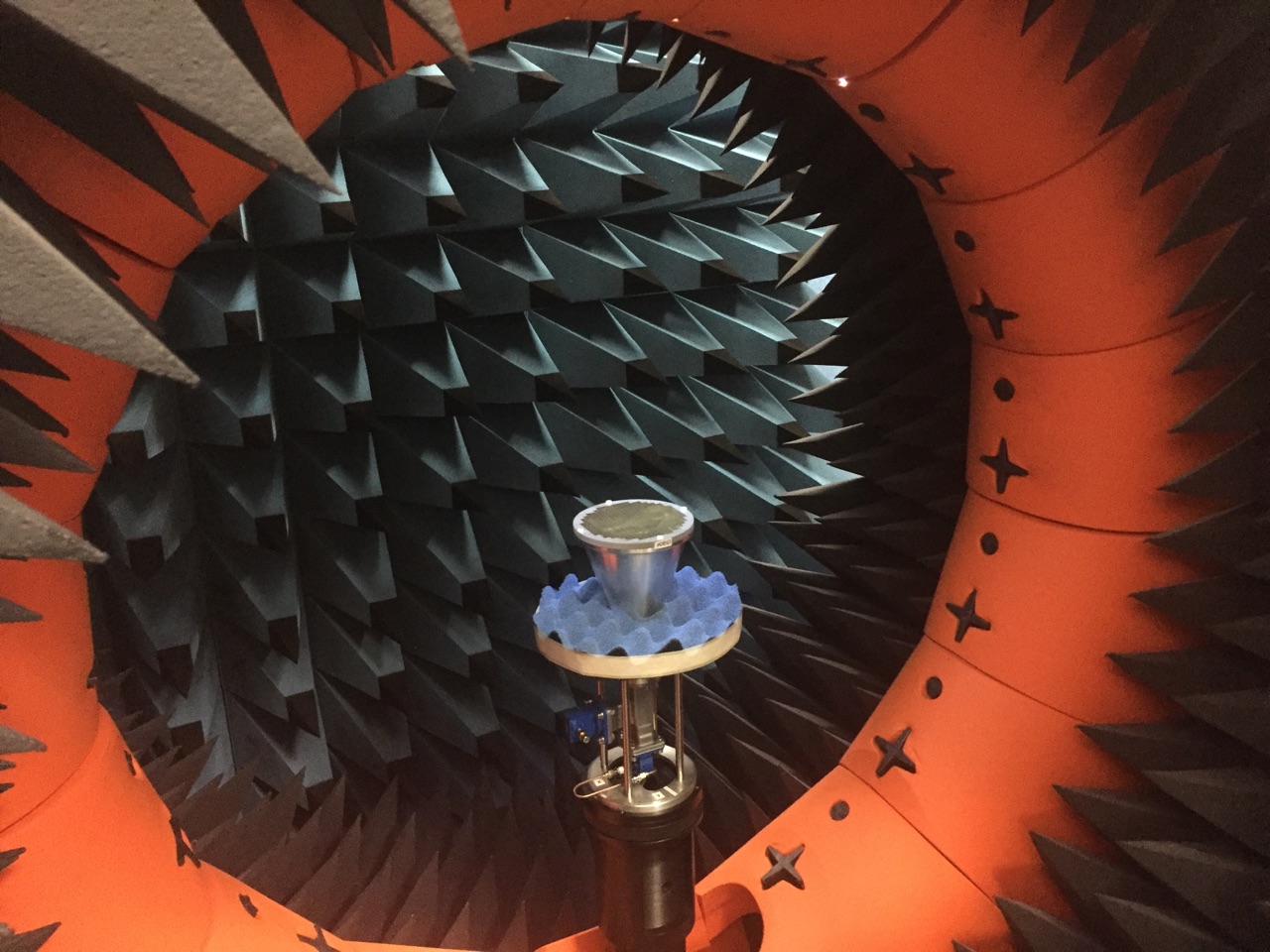

Image1.jpg (MVG)

Image2.jpg (MVG)

Image3.jpg (MVG)

Challenges

Design challenge:

- Broadband operation

- Conformal metasurface

- Implementation of a very wide range of equivalent impedances

- Metasurface unit cell optimization

- Analytical model for modes in conical horns with impedance boundary conditions

Modelling challenge:

- Automatic generation of the pixels from the planar to conical geometry

- Multi-Scale meshing (subwavelength pixel size)

- Large number of unknowns

- Ill conditioned problem

- Formulation for composite metallic and dielectric structures

- Acceleration method required

Fabrication challenge:

- Manufacturing of a dielectric based meta-surface conformal to a conical shape

- Manufacturing of stacked meta-lens with electrically small cells

- Definition of a complex manufacturing process including different fabrication technologies and autoclave based bonding procedures

- Handling of critical manufacturing tolerances and alignment requirements between parts constructed in different technologies

System Architecture

The system developed in the project to demonstrate the capabilities of the investigated technology is composed by four parts:

- Conical Metasurface horn

- Metasurface lens

- Launcher

- Ortho-Mode Transducer

Plan

Requirements definition

Preliminary design

Detailed design

Demonstration

Concurrent design tool update

Concept evaluation and evolution

Current Status

Completed