PAGE CONTENTS

Objectives

The project focuses on the development up to the preliminary design stage (PDR) of the OneSat enhanced Deployable Panel Radiator product (e-DPR) which is a key satellite element providing the spacecraft with the required heat rejection capability. Although some heritage was provided through the previous Alphabus or Eurostar developments, the concept was significantly modified to match the new satellite constraints in terms of size, accommodation, thermal rejection capability, mechanical behavior and overall required motions from stowed to fully deployed positions and then during the Spacecraft life with the ecliptic synchronous oscillations.

The first objective of the project was to increase the product maturity up to a level compatible with a Preliminary Design review focusing on technological testing to decrease the development risks and on establishing a product specification consistent with the satellite needs and the achievable product performances.

Challenges

The first challenge for that product was to cope with the system stringent demand in terms of power / heat rejection and requiring the implementation of several innovations:

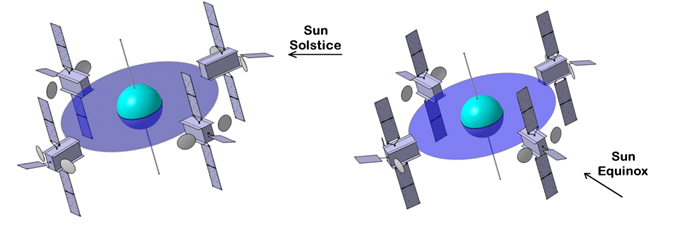

- The mechanism to keep the panels inside the ecliptic plan ensuring no sun illumination of the radiators and thus the best achievable performances.

- The capability to transfer the thermal fluid from the satellite towards the radiator and return through the set of articulations required to deploy the panels and keep them in the ecliptic plan.

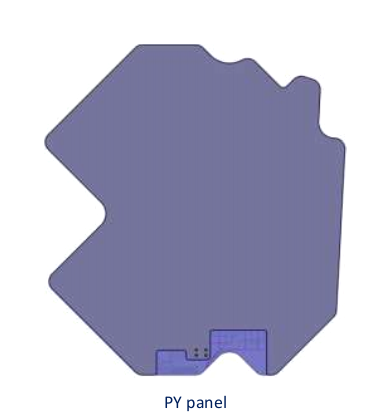

- The design of the panel and the implementation of a condenser network to spread the heat as much as possible while taking into account the potential failures or micro-meteoroid impacts. The panels themselves need to be as large as possible to maximise the rejection capability while remaining compatible with the Spacecraft geometry and complex accommodation constraints. This led to define a complex shape for the panels whose mechanical behaviour had to be carefully analysed.

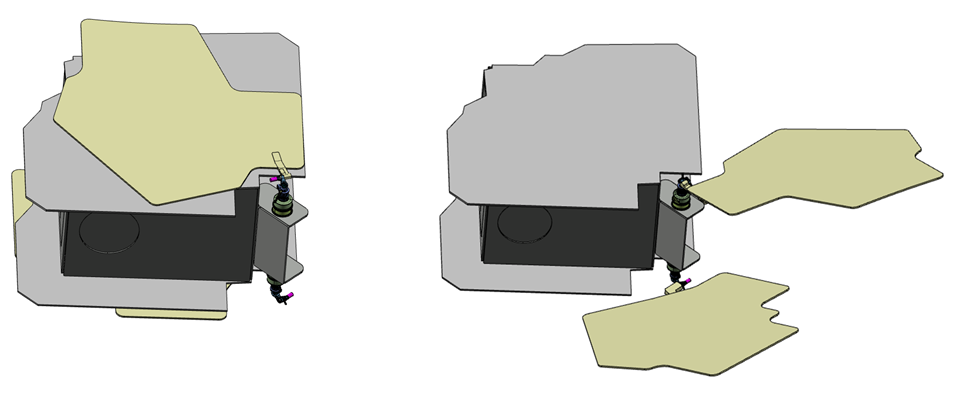

Additionally, the satellite life phases require the implementation of several mechanisms providing the first panel jump-out after spacecraft separation from the launcher, then for the panel deployment, then for the panel motion inside the ecliptic plan. This led to a quite complex design in terms of mechanism.

System Architecture

The eDPR is fully part of the Spacecraft thermal design. The heat is collected from the Active Antenna by the Loop Heat Pipes evaporator, then flowed towards the radiators through the DPR deployment and pointing system thanks to an ad-hoc pipe network, then evacuated towards the vacuum.

The panel shapes and motions from the stowed position to the fully deployed one are specific to OneSat geometry and designed to prevent any clash with the other many spacecraft appendices which may be deployed or not according to the satellite life.

All the panel motions are commanded by the On Board SW either automatically or according to ground commands.

Mechanically speaking, during the launch phase, the two panels are clamped to the spacecraft north and south faces using a set of dedicated Holding and Release Mechanisms.

Plan

The DPR development plan proposed in the frame of that ARTES contract covered the development up to the PDR phase with the following main milestones:

- The Kick-off to formally start the contract and assess the prior work

- The Requirement review where the OneSat main drivers or requirements were reviewed together with the results of the main design trade-offs. This phase of the development was done in a co-engineering way between the system and the product teams with the objective to achieve the best compromise between actual system needs, achievable performances, design complexity and development risks.

- The Preliminary design review whose objectives were to freeze the requirement specification, to present the preliminary design and performances, to identify the critical items together with the associated risk reduction actions, to approve the industrial set-up and to review the overall development and validation plan.

The eDPR development carries on in the frame of the Novacom 1 partnership project and will go through the critical design Review and the final qualification review.

Current Status

All the work planned to be done in the frame of this ARTES contracted has been successfully performed and the review successfully passed concluding on a safe design and development plan. Several “normal work” actions are to be closed for the Critical design Review.

The development is continuing in the frame of the OneSat Novacom Partnership Project.