PAGE CONTENTS

Objectives

The PATROL study aims to de-risk the technology required to make a cost effective LCT control electronics subsystem to execute robust Pointing Acquisition and Tracking (PAT) and Adaptive Optics algorithms on a single compact control platform.

The development and verification focus on breadboard activities to mitigate the technical risks identified in the development of the final product.

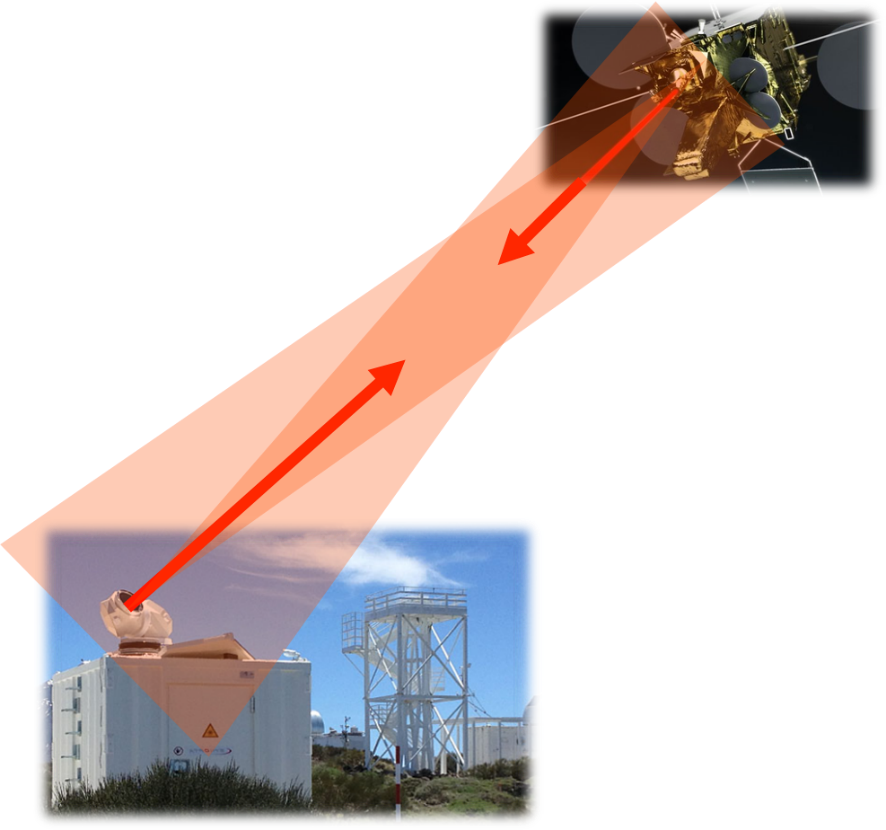

Laser Terminal System Companies need to establish and maintain a laser link between a satellite and a ground terminal at Tbps range data rates. Pointing, Acquisition and Tracking (PAT) is affected by noise sources (Propagation channel atmospheric noise, mechanical noise, electronics noise …). The objective of the PAT function is to be sufficiently robust to meet customer service availability requirements. Laser link shall not be lost, even in case of worsening atmospheric conditions and Bit Error Rate degradation.

The objective is to create a robust closed loop Optical Ground Terminal (OGT) control system, consisting of fast electronics, optronics (detectors, sensors), functionalities (e.g. windowing, synchronization, buffering, time stamping…) and a robust algorithm. The electronics are designed to have sufficient resources to accommodate Adaptive Optics processing also needed in high speed OGT.

Challenges

-

Embedded control platforms typically have limited computational resources available for sufficient control bandwidth. This makes implementation of a robust tracking algorithm challenging.

-

Embedded control platforms typically have limited Input/Output (I/O) bandwidth available for readout of acquisition and tracking sensors and commanding of tip/tilt actuators. This makes operation at the required control cycle challenging.

-

Application in a compact Optical Ground Station (OGS) or airborne terminal requires a small-size embedded control platform. Combined with the required computational resources this is challenging.

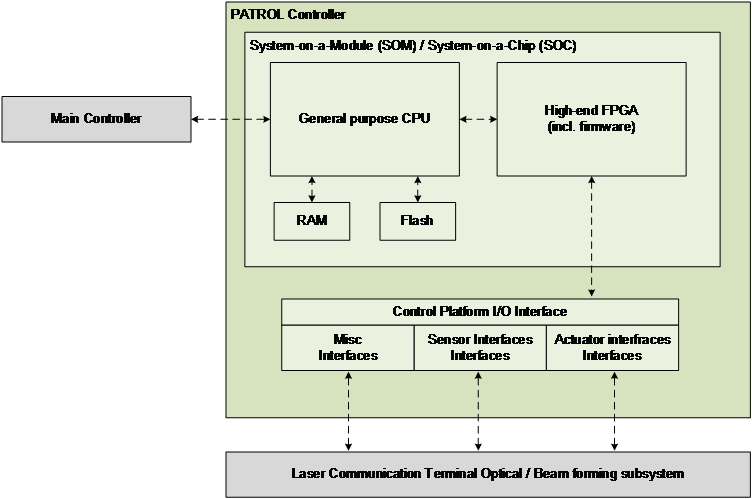

System Architecture

-

PATROL System-on-a-Chip (SOC): The control platform computational core, a SOC with general purpose CPU and high end FPGA

-

Control platform I/O section: The control platform electrical interfaces to PAT sensors and actuators

-

Control platform FPGA Firmware: FPGA programming for time critical parts of PAT algorithms. i.e. high frequency closed loop tracking function

-

Control platform software: Software for less time critical parts of PAT, such as state management and scanning path generation. Interfaces to time critical FPGA loop (not shown in figure)

Plan

Kick-Off (T0)

Milestone 1: Design Review (T0 + 5 months)

-

Approve final design

-

Assess adequacy of breadboard for technology demonstration

-

Review verification test plan.

Milestone 2: Test Readiness Review (T0 + 7 months)

-

Verify test documentation suitability

-

Verify that tested items are built to the required standard.

-

Check correct test configuration.

-

Verify acceptability of all non-conformances, waivers and deviations.

Milestone 3: Final Review (T0 + 11 months)

-

Present summary of outcome of the development phase, including conclusions and recommendations.

-

Propose outline of future product development strategies.

-

Present data gathered.

Current Status

The activity is kicked off in April 2021, and achieved Milestone 1 on January 2022.

Work currently in progress.