-

StatusOngoing

-

Status date2016-09-08

The Slipring is developed to be used in the new generation of SpaceBus Solar Array Drive Mechanism (SADM), for Thales Alenia Space platform.

The main challenges for the slipring were:

• the increase of power transfer capacity (16.5 kW à 27kW)

• The limited volume and length available

• The improve of the thermal design

The Angular Sensor was developed considering the following:

• Directly integrated on the rear side of the SlipRing

• Use reliable technologies for tribological contacts

• include both digital and analogic channels

AAS:

The design of the AAS is based on single brush/track contacts therefore the AAS design is sensitive to glitches issue. The AAS design must be modified in order to address efficiently the glitch issue

The AAS is not qualified today, but the work has been done according the initial plan and the qualification results are satisfactory in some parts. The glitches issue is the main cause of the functional tests failure during the qualification. Thanks to RUAG’s investigation, the phenomenon is better understood and design improvement have been proposed for the potential new generation of AAS

SRC:

The acceptance tests performed at RUAG have successfully demonstrated the G3 SRC QM performances. All the results were in the expected range and compliant

SRC.

- Compact slipring with high power capacity

- Optimized in mass and volume

- Plug& Play solution (connectors integrated)

SRC performance:

|

|

Power forward lines |

Power return lines |

Signal lines |

Grounding lines |

|

Number |

25 |

5 |

24 |

3 |

|

Current [A RMS] |

9 |

45 |

1 |

1 |

|

Voltage [V] |

120 |

120 |

120 |

- |

|

Properties |

Unit |

Value |

|

Mechanical configuration |

- |

Cylindrical slipring Bearing less with plain bearing at rotor end |

|

Housing diameter |

[mm] |

97 |

|

Overall diameter |

[mm] |

222 |

|

Length |

[mm] |

162.5 |

|

Maximum mass |

[kg] |

4.35 |

|

Power transfer |

[kW] |

27 |

|

Maximal heat dissipation |

[W] |

52 |

|

Qualification temperature range |

[°C] |

-50 ≤…≤ 140 |

|

Lifetime |

years |

18 |

AAS performances:

|

|

Description |

Unit |

Nominal |

Tolerances |

|

Nominal |

|

|

|

|

|

Channel 1 |

Step size |

[°] |

180 |

±0.5 |

|

|

Angular deviation of electrical zero wrt. Mechanical zero at delivery |

[°] |

0 |

±0.2 |

|

|

repeatability |

[+/-°] |

0 |

±0.094 |

|

Channel 2 |

Step size sectors |

[°] |

5, 9, 11 |

±0.13 |

|

|

Angular deviation of CH2 electrical zero wrt. CH1 electrical zero |

[°] |

0 |

±0.2 |

|

|

repeatability |

[+/-°] |

0 |

±0.106 |

|

Channel 3 |

Step size |

[°] |

5 |

±0.15 |

|

|

Angular position of CH3 electrical zero wrt. CH1 electrical zero |

[°] |

182.5 |

±0.614 |

|

|

Repeatability |

[+/-°] |

0 |

±0.111 |

|

Redundant |

|

|

|

|

|

Channel 1 |

Step size |

[°] |

180 |

±0.5 |

|

|

Angular deviation of electrical zero wrt. Mechanical zero at delivery |

[°] |

0 |

±0.2 |

|

|

Angular deviation of redundant electrical zero wrt. nominal electrical zero |

[°] |

0 |

±0.4 |

|

|

repeatability |

[+/-°] |

0 |

±0.139 |

|

Channel 2 |

Step size sectors |

[°] |

5, 9, 11 |

±0.13 |

|

|

Angular deviation of CH2 electrical zero wrt. CH1 electrical zero |

[°] |

0 |

±0.4 |

|

|

repeatability |

[+/-°] |

0 |

±0.13 |

|

Channel 3 |

Step size |

[°] |

5 |

±0.15 |

|

|

Angular position of CH3 electrical zero wrt. CH1 electrical zero |

[°] |

182.5 |

±0.614 |

|

|

repeatability |

[+/-°] |

0 |

±0.149 |

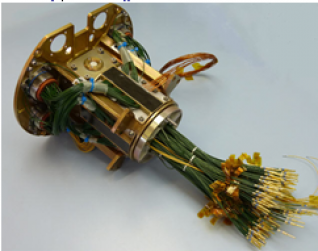

SRC picture:

Qualification completed end of 2014. Manufacturing of FM units in 2015, delivery of FM beginning of 2016.

AAS picture:

Qualification completed mid-July 2015. No PFM/FM foreseen.

SRC:

- 6 Sliprings have been already delivered for commercial telecom application

AAS:

- Angular Sensor went to all the qualification tests. Final customer decided to not use it in their SADM.