-

StatusCompleted

-

Status date2025-05-23

-

Activity Code5G.025

We have a wide range of positioning systems, some of which have outstanding properties. We have received several requests for products for applications in space. In principle, our systems appeared to be suitable for the requirements. One of our tilting systems was tested by Thales Alenia Space in 2017 as part of a preliminary investigation and declared suitable.

In the specific project, the alignment of the beam must be maintained in the presence of various sources of misalignment. These include atmospheric aberrations and disturbances on the vehicle or satellite platform, which can originate from active elements and have a relatively high frequency signature.

These beam shifts can then be measured with a tracking sensor, for example, and compensated for in a closed control loop with a fine control mirror (FSM). A similar application is the so-called point-ahead mechanism (PAM). This creates an offset angle between the transmit and receive beams to compensate for satellite movement during the time of flight of the laser light.

By and large, our system met the typical specifications of both the FSM and PAM applications and thus offers a solution for two tasks that can significantly reduce the integration effort for such optical systems.

What our systems still lacked was proof of their suitability for all applications. Therefore, after discussions with our organisation, DLR, we decided to apply for the ARTES 4.0 Optical Communication/Skylight, Technology & Product Developments project.

The main challenge within the project is to design a system that meets the technical criteria of both typical FSM and PAM applications with sufficient tilting angles and high frequency response over a wide temperature range. In addition, the system needs to offer outstanding lifetime and superior robustness to withstand shock and vibration during launch while being compact in size and cost efficient in production.

The utilisation of piezoelectric actuators in a fast beam steering mechanism provides several benefits. As a solid-state-effect, piezoelectric motion shows no mechanical play and theoretically unlimited positioning resolution. This allows for the highest pointing accuracy of the optical systems. Due to their capacitive nature, piezo actuators do not consume electrical power while holding a position. This makes them an ideal choice for space applications, where low power consumption is mandatory.

With the design of a system that meets the specifications of both FSM and PAM applications we provide one solution for two different problems. This results in a reduction in both costs and integration effort.

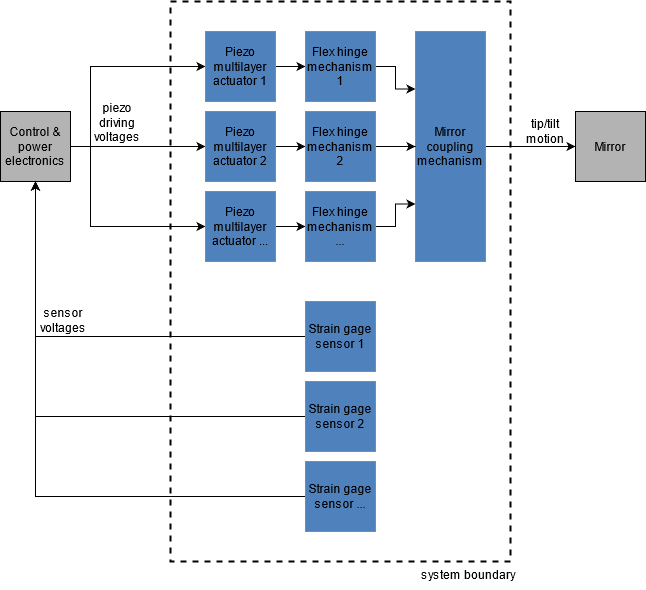

The system features a number of piezoelectric multilayer actuators that are able to convert an electrical input signal into a motion. A sophisticated mechanical amplification and guiding mechanism transfers the motion into a tilting angle of the mirror holder and the mirror. The motion is measured with a set of position sensors that enable a closed loop control of the two-dimensional angular motion of the mirror.

The whole mirror tilting system is specially tailored for space operation resulting in:

- mass reduction

- size reduction/ construction space adaptation

- increased stiffness

- high robustness to withstand shock and vibration during launch

- wide operating temperature range

- high lifetime

The mirror tilting system consists of several piezo-electrically actuated flex hinge designs, which are coupled to a mirror holder. The main components of the product are:

- The piezo multilayer actuators, converting electrical energy into motion.

- Several flex hinge mechanisms, which amplify the input motion of each piezo into an output motion with larger stroke and smaller force.

- A coupling mechanism, which transforms these motions into mirrors tilting angles.

- Several strain gage sensors to measure the tilting angles.

The project includes two phases, a technology phase and a product phase. In the technology phase, work is carried out on basic components, designs and methods in order to realise the objectives formulated in the project.

The results of this first phase will be verified using a engineering model and used as the basis for the realisation of the space-qualified tilting system as the final engineering qualification model in the subsequent product phase.

The technology phase of the project was successfully completed with proof of the targeted specifications based on the engineering models that were set up. Preparations for the following product phase are currently underway.