-

StatusCompleted

-

Status date2025-09-28

-

Activity Code4D.056

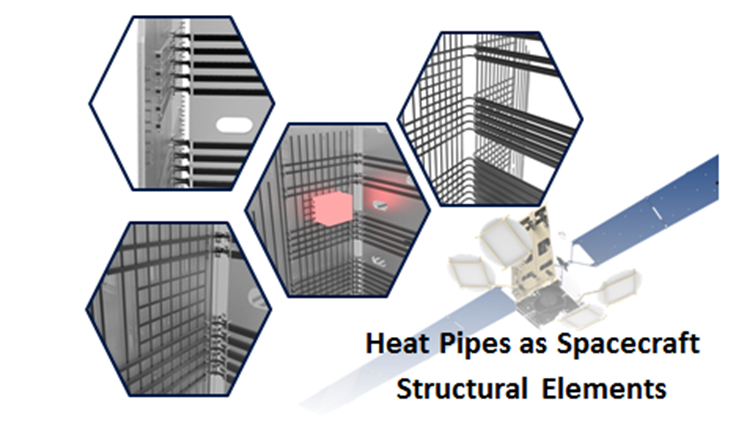

In current spacecraft design, structural strength of the satellite is primarily attributed to the main structural elements; namely the central tube, various panels, and mechanical brackets/joints. Heat pipes are typically rigid metallic (e.g. aluminium alloy) tubes that are attached to structural/equipment panels, radiators and equipment. However they are considered as thermal products and protected in order that they are as little as possible mechanically loaded to ensure that thermal function. It means that all of that metallic mass is unused from a structural point of view. It can even become a constraint to prevent its mechanical loading, increasing the mass of structural parts.

That situation is far from ideal and is becoming more and more concerning with the increase of power dissipated by payloads. In an ideal situation, heat pipes would be used both as thermal elements as today, but also as structural elements thanks to the good mechanical properties of their aluminium material. Of course it must be ensured that this new use will not be detrimental to the thermal properties of the heat pipes, especially at the joint with the panel or equipment.

The key challenge of the project is to assess the strength allowable of the heat-pipes in the respective use-cases, depending on their local geometry and bending. The effect of load introduction depending of the types of interfaces is also a challenging aspect to understand, in order to provide improved design rules for their integration within the spacecraft main structure.

This project aims at studying the use of heat pipes as structural elements with the goal to bring an improvement to satellite designs.

The improvement can be a mass reduction, a reduction of assembly and integration complexity (as heat pipes could replace some existing structural brackets) and other potential benefits to be identified during the project.

Thanks to this project, heat-pipes are proven to be able to be used as spacecraft structural elements with the following features:

- Standardised design rules for the mechanical interface of equipment directly to heat-pipes;

- Reduction of the need of additional mechanical interfaces (cleats, inserts);

- No design modification or additional structural elements required, the standard heat-pipe profile can be used as-is;

- No impact on the qualification status of heat-pipe operational temperature range or thermal performance.

Usage of these heat-pipes as structural elements are primarily proposed for the current implementations of embedded and surface heat-pipes in telecom spacecraft. Taking into account their strength in the overall spacecraft structural performance will help better correlation of the spacecraft main vibration modes, limit platform mass and decrease the complexity of interfaces (reduction of existing structural brackets between walls and the number of honeycomb inserts).

New usages of heat-pipes are also proposed, to improve the available accommodation surface of payload equipment, by a better usage of the current walls, or by the creation of additional accommodation options with secondary structures made of heat-pipes.

The project is organized in three parts:

- First objective is the definition of the most promising use cases where structural usage of the heat pipe can bring significant improvement to the spacecraft design and performance;

- Then, first static test campaign at unitary level to correlate the structural performance of the critical areas and define design rules with allowable strength limits;

- Finally, a Cycling Breadboard, representative of Heat Pipe usage as structural elements in the most representative use cases, validates the compliance of the heat-pipes used as structural element in a telecommunications spacecraft environment, by completing a qualification campaign representative of the overall life-time of an item sent to a telecom mission in geostationary orbit during 15 years.

The project is now completed, with full validation of the design rules on the most valuable heat-pipe application in telecommunications applications. Extensions are also ready for other types of usages, with propositions of delta-qualification and remaining development plan.